Researchers from North Carolina State University have found that an elastic polymer possesses broad-spectrum antimicrobial properties, allowing it to kill a range of viruses and drug-resistant bacteria in just minutes – including methicillin-resistant Staphylococcus aureus (MRSA).

“We were exploring a different approach for creating antimicrobial materials when we observed some interesting behavior from this polymer and decided to explore its potential in greater depth,” says Rich Spontak, co-corresponding author of a paper on the work and Distinguished Professor of Chemical and Biomolecular Engineering at NC State. “And what we found is extremely promising as an alternate weapon to existing materials-related approaches in the fight against drug-resistant pathogens. This could be particularly useful in clinical settings – such as hospitals or doctor’s offices – as well as senior-living facilities, where pathogen transmission can have dire consequences.”

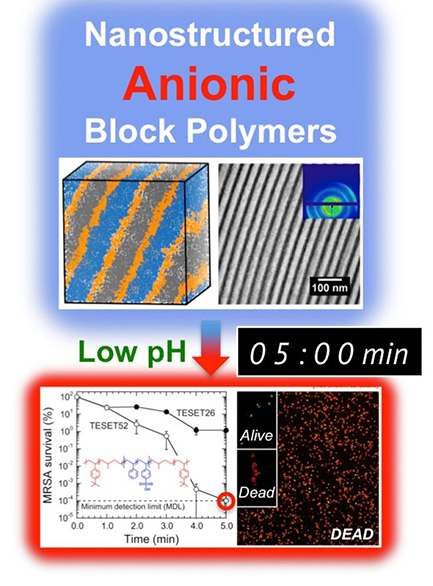

The polymer’s antimicrobial properties stem from its unique molecular architecture, which attracts water to a sequence of repeat units that are chemically modified (or functionalized) with sulfonic acid groups.

“When microbes come into contact with the polymer, water on the surface of the microbes interacts with the sulfonic acid functional groups in the polymer – creating an acidic solution that quickly kills the bacteria,” says Reza Ghiladi, an associate professor of chemistry at NC State and co-corresponding author of the paper. “These acidic solutions can be made more or less powerful by controlling the number of sulfonic acid functional groups in the polymer.”

The researchers tested the polymer against six types of bacteria, including three antibiotic-resistant strains: MRSA, vancomycin-resistant Enterococcus faecium, and carbapenem-resistant Acinetobacter baumannii. When 40% or more of the relevant polymer units contain sulfonic acid groups, the polymer killed 99.9999% of each strain of bacteria within five minutes.

The researchers also tested the polymer against three viruses: an analog virus for rabies, a strain of influenza and a strain of human adenovirus.

“The polymer was able to fully destroy the influenza and the rabies analog within five minutes,” says Frank Scholle, an associate professor of biological sciences at NC State and co-author of the paper. “While the polymer with lower concentrations of the sulfonic acid groups had no practical effect against human adenovirus, it could destroy 99.997% of that virus at higher sulfonic acid levels.”

One concern of the researchers was that the polymer’s antimicrobial effect could progressively worsen over time, as sulfonic acid groups were neutralized when they interacted with positively charged ions (cations) in water. However, they found that the polymer could be fully “recharged” by exposing it to an acid solution.

“In laboratory settings, you could do this by dipping the polymer into a strong acid,” Ghiladi says. “But in other settings – such as a hospital room – you could simply spray the polymer surface with vinegar.”

This “recharging” process works because every time one of the negatively charged sulfonic acid groups combines with a cation in water – which can happen when the polymer comes into contact with microbes – the sulfonic acid group becomes electrically neutral. That makes the acid group ineffective against microbes. But when the neutralized polymer is subjected to acid, those functional groups can exchange bound cations with protons from the acid, making the sulfonic acid groups active again – and ready to kill microbial pathogens.

“The work we’ve done here highlights a promising new approach to creating antimicrobial surfaces for use in the fight against drug-resistant pathogens – and hospital-acquired infections in particular,” Ghiladi says.

“Functional block polymers like this are highly versatile – usable as water-treatment media, soft actuators, solar cells and gas-separation membranes – and environmentally benign since they can be readily recycled and re-used,” Spontak adds. “These features make them particularly attractive for widespread use.

“And this work focused on only one polymer series manufactured by Kraton Polymers,” Spontak says. “We are very eager to see how we can further modify this and other polymers to retain such effective and fast-acting antimicrobial properties while improving other attributes that would be attractive for other applications.”

See Full Press Release: Self-Sterilizing Polymer Proves Effective Against Drug-Resistant Pathogens | NC State News

Written by: Matt Shipman

Legacy MedSearch has more than 30 years of combined experience recruiting in the medical device industry. We pride ourselves on our professionalism and ability to communicate quickly and honestly with all parties in the hiring process. Our clients include both blue-chip companies and innovative startups within the MedTech space. Over the past 10 years, we have built one of the strongest networks of device professionals ranging from sales, marketing, research & , quality & regulatory, project management, field service, and clinical affairs.

We offer a variety of different solutions for hiring managers depending on the scope and scale of each individual search. We craft a personalized solution for each client and position with a focus on attracting the best possible talent in the shortest possible time frame.

Are you hiring?

Contact us to discuss partnering with Legacy MedSearch on your position.